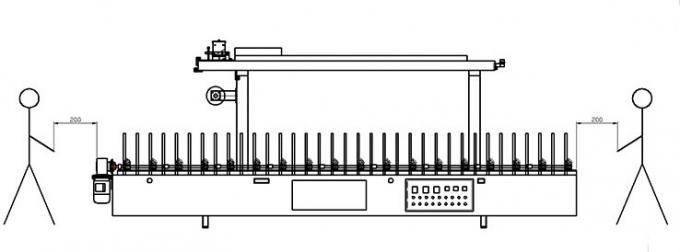

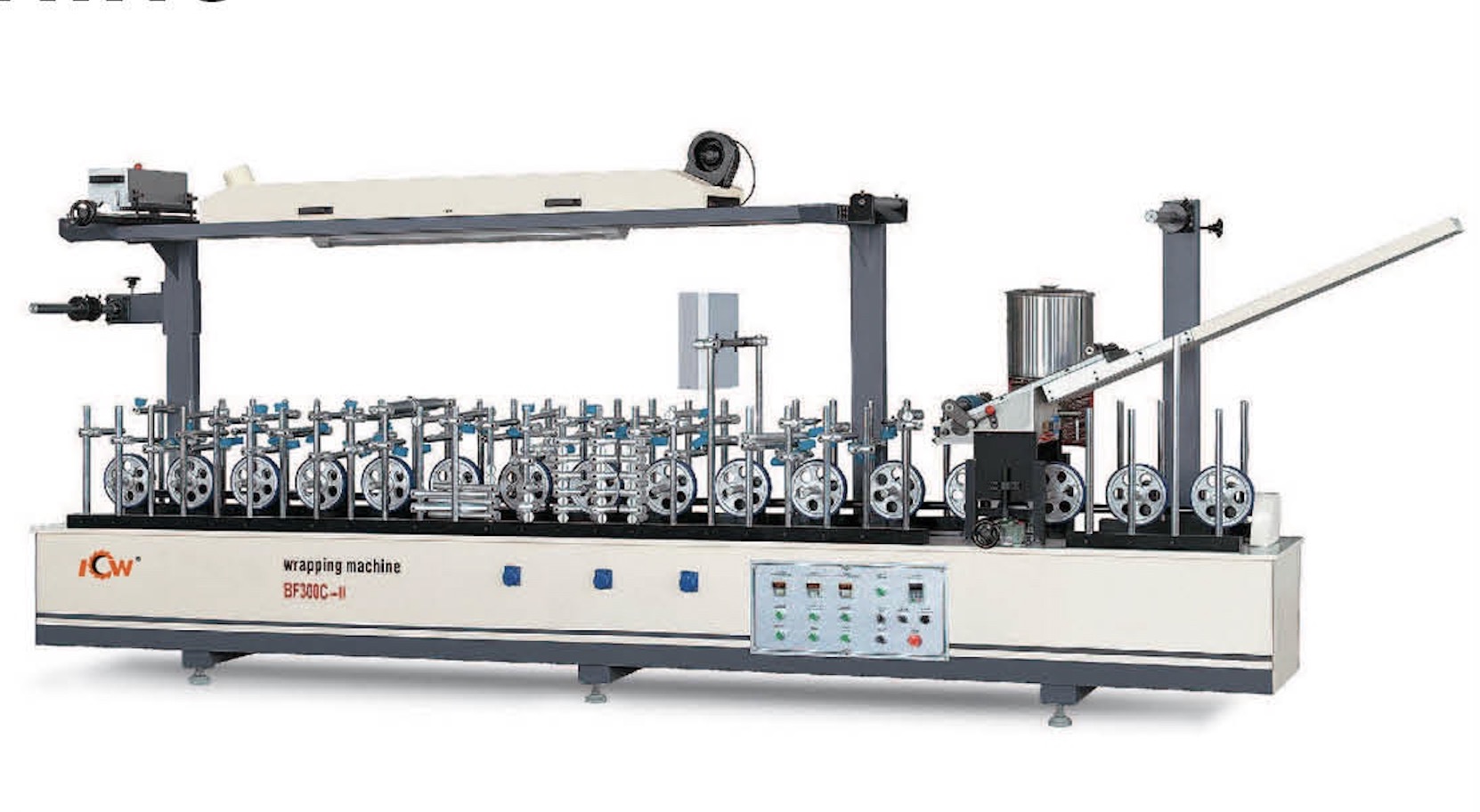

This machine is equipped with two or fours changeable wrapping zone .while the machine is producing ,another wrapping zone can be prepared to produce the next type of profile .the coupling of the wrapping units is done very fast .avoiding long production stops caused by the setting up of the molding rollers to produce another different profile.

A full set of manufacturing processes can be full automatic assembly line,the normal working can be done without human intervention,it just need to feed material from adhesive coating to expectthe sending until the product be finished.which reduce labor costs and ensure the passing rate of processed products and processing efficiency.

1.This machine uses high quality steel and connects with bolt rather that welding so as to avoid disfigure of the framework. High accuracy gear transmission, mechanical stepless speed change in the electrical engine adopts stepless timing

2.The bottom wheels are all made by silicon rubber and aluminum. They are wearable and not sticky to the glue. And it can be used long.

The Features of profile wrapping machinery .

1.This machine uses high quality steel and connects with bolt rather that welding so as to avoid disfigure of the framework. High accuracy gear transmission, mechanical stepless speed change in the electrical engine adopts stepless timing

2.The bottom wheels are all made by silicon rubber and aluminum. They are wearable and not sticky to the glue. And it can be used long.

3.The glue plate can be moved upward or downward according to the height of the work piece so that the wrapping can go smoothly.

ICW SOLUTION Since 2004 Manufactured And Marketed

A comprehensive range of technologies and solutions for Furniture | Doors | Cabinets.

ch

ch English

English