1. Users are not allowed to adjust the high-pressure roller and the sanding amount should not be too large, which is easy to cause the workpiece to hit back and hurt people.

2. The grounding of the machine must be reliable. It is strictly forbidden for non electrical professionals to connect power to the machine or repair the electronic control system. It is strictly forbidden to repair the machine with live line. Professional electrical personnel should conduct regular electrical safety inspection on the machine. Do not dismantle or change the safety protection device of the machine without permission.

3. The dust removal pipe of the machine should be made of metal materials and have good grounding, which is particularly important for grinding paint and resin materials, or it may cause fire due to electrostatic discharge and dust explosion in serious cases.

On the premise of no fault, the main power must be turned off when all the belt stops, otherwise the belt will run out and the photoelectric and travel switch will be damaged.

The transformer can not be connected with any external load, and can only be used by this machine.

PRODUCT DESCRIPTION

| Model | WBS130KRP | WBS130KR | WBS100KRP |

| Width of sanded panel | 40-1300mm | 40-1300mm | 40-1000mm |

| Thickness of sanded panel | 3-120mm | 3-120mm | 3-120mm |

| Speed of planing roller | 30m/s | 30m/s | 30m/s |

| Speed of abrasive belt on 2nd unit | 18m/s | 18m/s | 18m/s |

| Speed of abrasive belt on 3rd unit | 12m/s | —— | 12m/s |

| Feeding speed | 6-30m/min | 6-30m/min | 6-30m/min |

| Size of abrasive belt | 1330×2500mm | 1330×2500mm | 1330×2500mm |

| Diameter of planer | Φ180mm | Φ180mm | Φ180mm |

| Roller diameter | Φ270mm | Φ270mm | Φ270mm |

| Power of planing roller | 22kw | 22kw | 18.5kw |

| Power of abrasive belt on 2nd unit | 22kw | 22kw | 18.5kw |

| Power of abrasive belt on 3rd unit | 15kw | — | 11kw |

| Conveyor motor power | 4Kw | 4Kw | 4Kw |

| Lifting motor power | 0.25Kw | 0.25Kw | 0.25Kw |

| Brush motor power | 0.37Kw | 0.37Kw | 0.37Kw |

| Working pressure | 0.55MPa | 0.55MPa | 0.55MPa |

| Compressed air consumption | 0.2m3/h | 0.2m3/h | 0.2m3/h |

| Pressure relief device required | >13000m3/h | >13000m3/h | >13000m3/h |

| Speed required for cleaning equipment | 25-30m/s | 25-30m/s | 25-30m/s |

| Dimensions | 2500×2260×2180mm | 2500×1850×2180mm | 2500×1960×2180mm |

| N.W. | 4000kg | 3500kg | 3500kg |

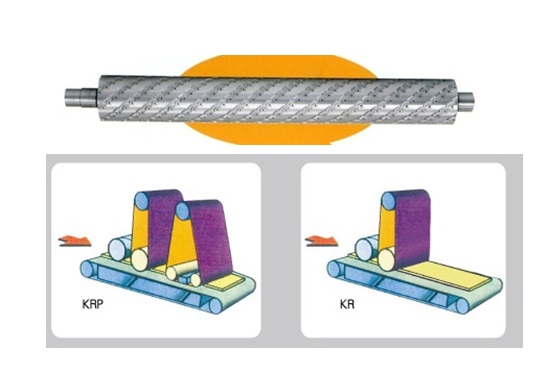

Planer and sander is mainly used for solid wood board, panel, finger joined panel, door, flooring etc, with advanced technology, high precision, reasonable structure and easy operation

Characteristic

1With super large helical cutter can work stable

2 Cut off a big quantity with lower noisy and fine surface

3 With anti-tick device to protect operator

4 Wooden dusts is cleaned by the brusher

5 Machine will not start when air pressure is not enough.

6 Adopt pressure shoes to avoid damaging the head of panel during sanding.

ICW SOLUTION Since 2004 Manufactured And Marketed

A comprehensive range of technologies and solutions for Furniture | Doors | Cabinets.

ch

ch English

English