Heavy-duty cnc machine center with aging treatment ensures higher accuracy.

This model machine is suitable for producing complex production.Famous brand parts

ensures

stability of machine such as Germany helical gear or Taiwan linear rail.

Auto labeling machine will monitor total labeling process and check if label is lost or if printing

failure,

which ensures 100 percent correction for auto labeling.

Tool magazine with servo motor driver,which reduces tool change time,increases efficie

ncy of production.

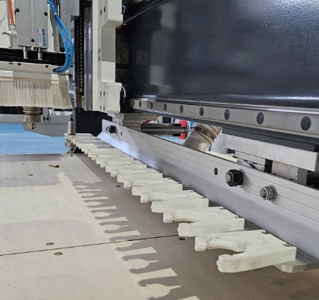

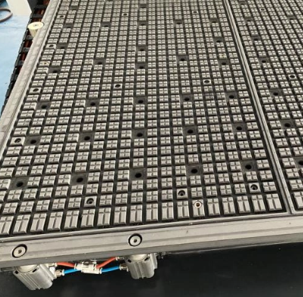

Double -layer vacuum table ensures much more absorption ability.

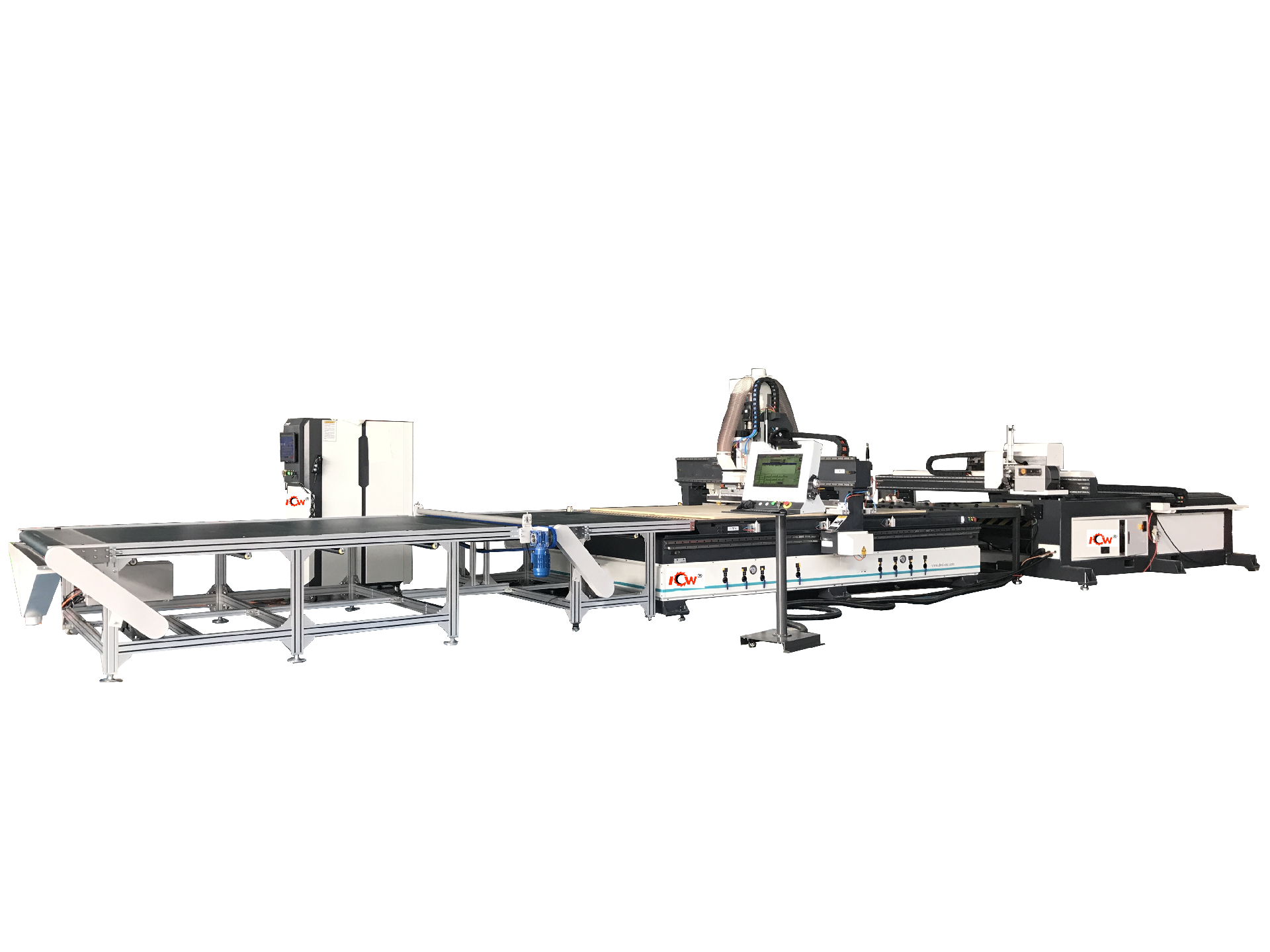

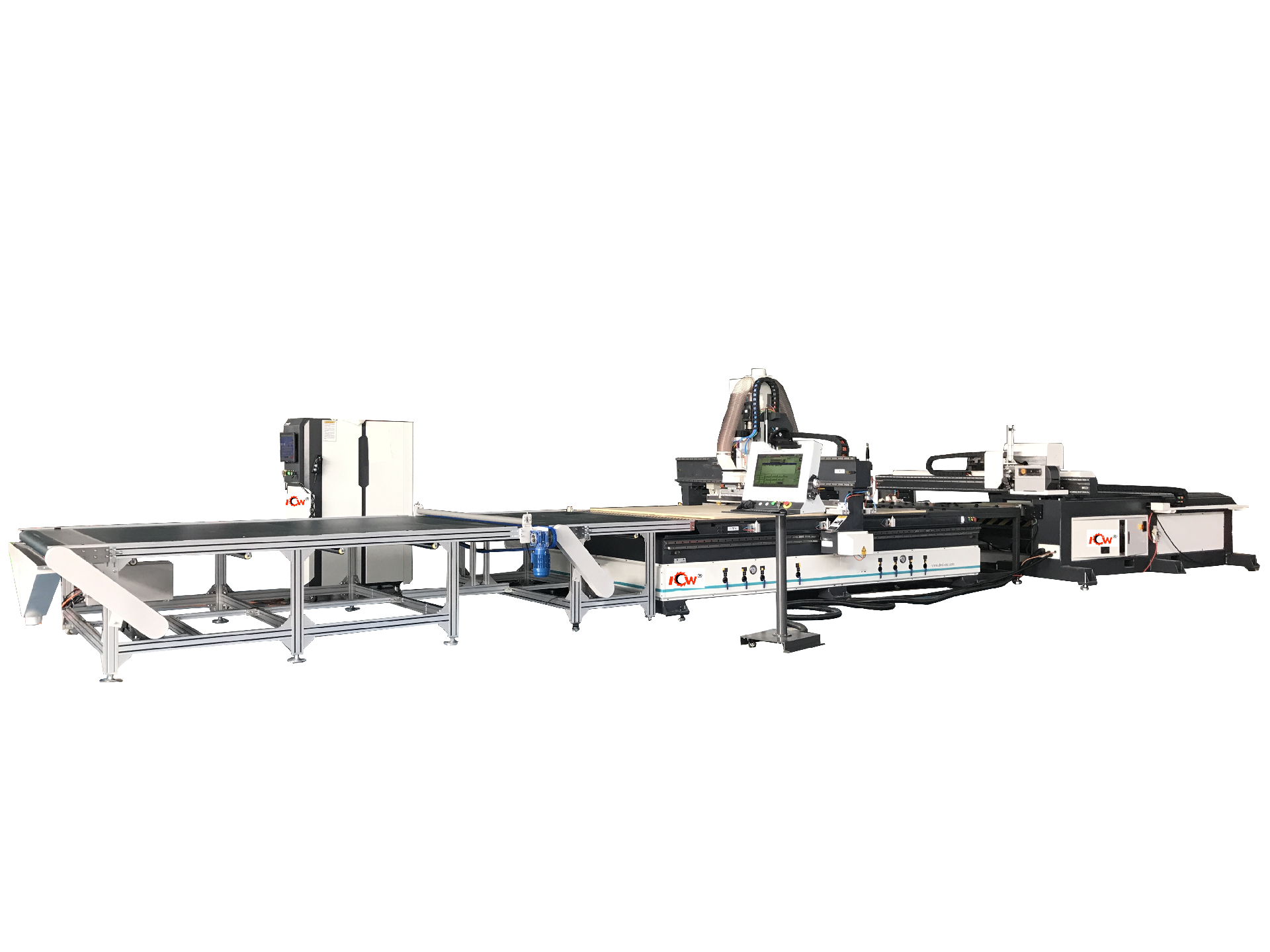

The CNC Nesting Machine Center automatically labels on the sheet,

and then it will load a 4x8 / 4x9 /6x9/7x9 /5x10 sheets etc, from a pallet by way of a scissor lift located at the rear of the CNC Nesting

machine. A movable gantry system equipped with suction cups using retractable guide rails and stops on the table safely and accurately guides the material sheet onto the CNC platform. Once the sheet is placed, the vacuum hold down automatically and operator starts the cut cycle for the CNC to execute. At the same time, machine will start to label on next sheet. After the sheet is fully processed, it is then pushed off to a conveyor table at the front end while another finished labeling sheet is simultaneously loaded from the rear of the machine again. During this whole process the residual dust or chips that are not picked up from the dust collector are swept off the table and conveyor into various chutes keeping the work cell clear of dust and debris. Upon completion, the individual parts are labeled by the operator through an integrated bar code system. This facilitates clear identification of the finished parts for quick and easy assembly later on.

This model machine is designed according to European market.

As in European country, panel size normally is 2070*2745mm,

so we designed working size to be 2100*2800mm.

America Zebra printer installed beside of gantry, so before drilling and cutting,

machine will print all labels and paste it on correct position automatically.

And there is unloading device installed under gantry,

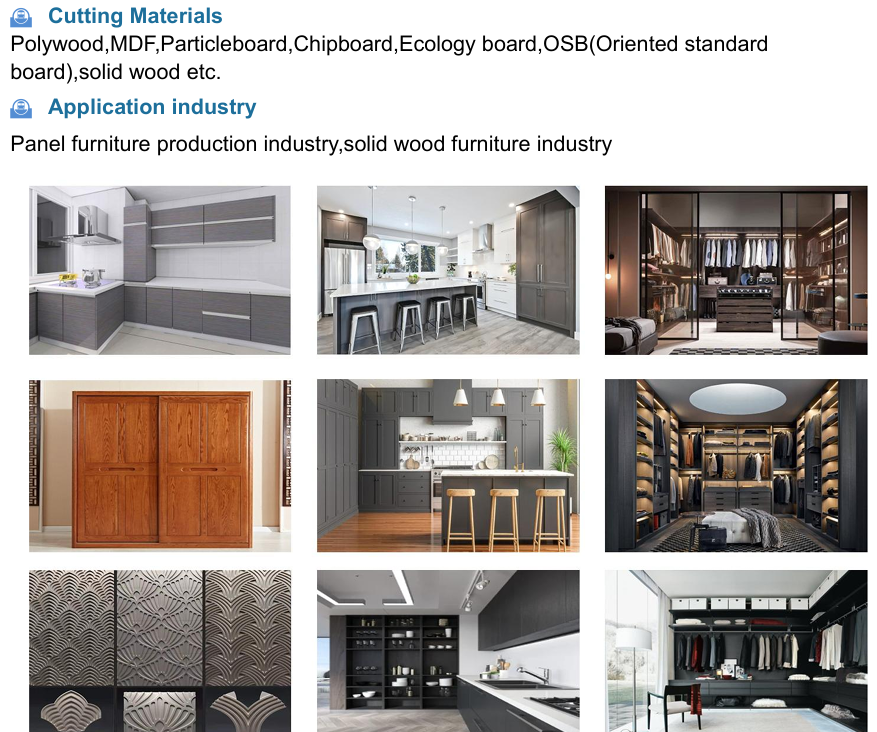

after cutting ,this machine can unload all finished panels to the front belt(this is optional part),which will save a lot of worker's labor.Except panel furnitures,

this machine can also do other work and cut all the other material

FEATURES 12HP CC 9.0kw spindle, ISO30 With loading scissor lift table and unloading conveyor belt Automatic labeling Maintenance free servo motor and driver 12-position rotary tool magazine Double-layer cnc nesting vacuum table New dust-free design for dust collector hood Vacuum pump 7.5kw 250m3/h It works with all industry standard CAD/CAM software Haixun Yunxi XXY etc |

MACHINE DETAILS:

1 | Big working size The working size of 2100*2800mm is suitable for the European standard panel dimensions. |

|

2 | Automatic labeling Equiped with America Zebra printer, this machine can labeling before drilling and cutting, besides installed beside of gantry ,no big area for this machine working . |

|

3 | Spindle It comes standard with 12HP air cooling automatic tool change spindle with standard ER32 collet and ISO30 tool holders.Its spindle speed is from 3000 to 24000RPM

|

|

4 | Dust free vacuum hood It is specially designed for panel furniture production.There are air blast in four different directions, so when tool cutting the panel, air will blow dust up, then dust collector can remove 90 percentage dust by pipes. |

|

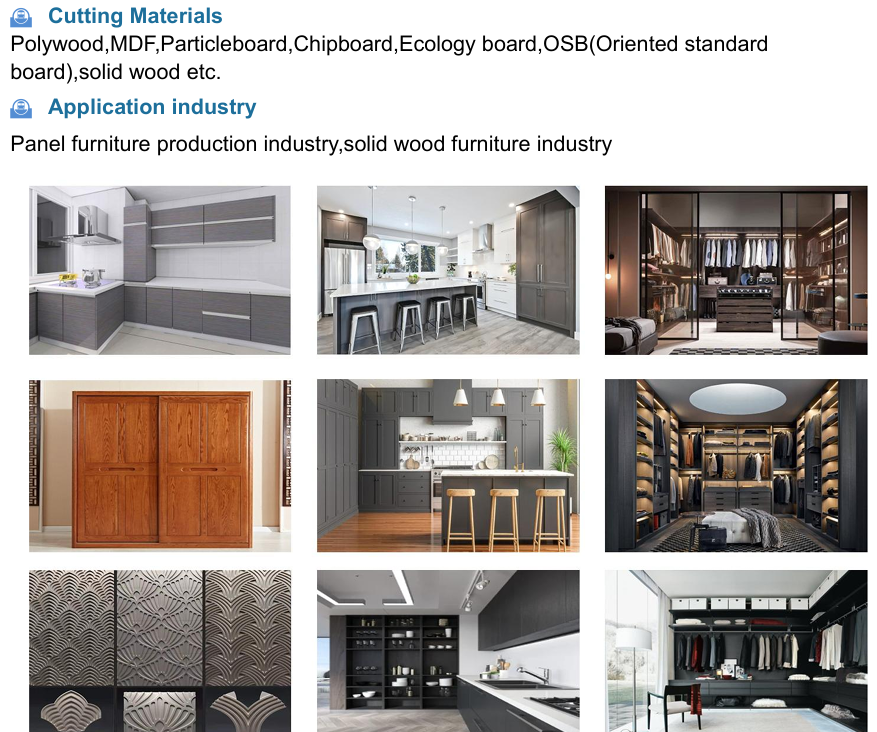

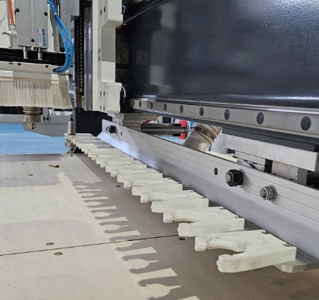

5 | Material alignment stops These material alignment stops plays a very important role during panel alignment. It can keeps panel positions so there is no need for operator to change working origins always, they just need set it one time.And it is very important in wardrobe cabinet production.Because sometimes we need drill holes on one panel both sides, those alignment stops will keeps accuracy of those holes. |

|

6 | 12 position linear tool magazine This linear tool magazine is installed back of machine ,and under tool magazine, we installed one protect cover . If tool drops out of plastic tool pocket,this cover will protect tool from dropping to the floor and damage |

|

7 | Nesting vacuum table There is one big vacuum chamber between two layer of nesting vacuum table,this will improve absorption capability of vacuum table, thus panel material will be hold tightly.Besides we have installed big screws in vacuum table which are used to fix sacrificed MDF sheet,it is much more easier for operator compared to gluing.

|

|

8 | Tool calibration Automatic tool calibration will measure all tools length automatically,thus controller will know very accurate length of each tool, then machine will finish multi tool process smoothly. Besides there is one air pipe beside the tool calibration, before tool calibration, the air pipe will open to remove dust on the surface of tool sensor, which will keeps high accuracy |

|

9 | Tool holder clamp This holder clamp supply one easy way for operator to change tool manually only with one ER32 wrench.Compared normal way to tight collet nut with two wrenches,this way is not only safer,but also it can protect tools in the spindle. |

|

10 | Automatic unloading device After cutting, this device can unload all finished panels ,which saves a lot of time for picking up panels. |

|

11 | Plastic drag chain We separate encoder cable ,motor cable,and air pipe when we install then into plastic drag chain by plastic isolator. Thus encoder signal will not affacted by motor cable with high voltage,at the same time, it will protect those cables and pipes. |

|

ADVANTAGE OF THIS MACHINE: |

1 Automatic Label Function:Cause big working size of panel, it is not easy to paste label manually,so this automatic label function will be very efficient and important. Machine will paste labels on the panel,after that machine will drilling slotting and cutting. 2 Dust-Free Cutting Technology: Adopts advanced dust-free cutting technology to ensure no residue dust during cutting, maintaining a clean work environment thereby improving work efficiency. 3 Movable Dust Collection Device:Equipped with this special design, no need to install longer dust collector pipes,enhancing equipment durability. |

FREQUENT ASKED QUESTIONS: |

1 What is maximum cutting size of this machine? Or Can i customize maximum cutting size of nesting cnc machine? The maximum cutting size of this nesting cnc router is 2100*2800mm,which is suitable for European panel size 2070*2800mm. And you can also customize machine size if you have bigger size needed. 2 Will there be instructions attached with machine,which i can follow to learn how to operate this cnc nesting machine? There is one pen driver attached in machine tool box, in which there is instructions operation and maintenance,besides we have YouTube videos to show installation and operation of cnc router machine,except all of this ,you can choose to video chat with our engineer directly. 3 What g-code does the machine read?Can we integrate a post processor into our current software? As this machine has auto labeling function ,so except standard .NC file,it also need XML and BMP pictures for label.You can ask sales engineers to send you detail format and explanation of files and show it to your software supplier. But this machine can definitely work with your software for sure. 4 Is there any other optional for this nesting cnc? You can choose automatically loading and unloading table for this machine,and also you can choose one drilling head for this machine. 5 We need a Declaration of Conformity, CE certificate, does this machine have it? Yes,there is CE certificate and Declaration of Conformity for this machine. |

ch

ch English

English