CNC Side Drilling With CNC Nesting Machine Workstation

CONFIGURATION:

Upper and bottom drill group | PROTEAN/CHANGHCUAN |

UPPER DRILL SPINDLE | LINGYI 6KW*1 |

BOTTOM DRILL SPINDLE | LINGYI 3.5KW*1 |

DRILL GROUP POWER | UPPER DRILL GROUP 2.2KW*1 BOTTOM DRILL GROUP 2.2KW*1 |

SPINDLE POWER | 9KW*1SPINDLE MOTOR |

SERVO | Niemeher, Germany |

Straight line spindle | LINGYI 9KW*1 COOLING SPINDLE |

Drag Chain | IGUS ,GERMANY |

Guide Rail | Steel strip Rail FANT |

RACK | Hedical rack ,Germany |

Electronics | SCHNEIDER |

REDUCER | oriental planet |

Voltage | AC380V/3PH/50Hz |

Oil injection system | automatic |

Inverter | 7.5KW+7.5KW+11KW DINGSHEN |

Vacuum pump | 7.5KW water cycle pump |

Machine body | International standard for rectangular tube welding |

Frame appearance | Plastic spraying |

Total power | 34.5KW |

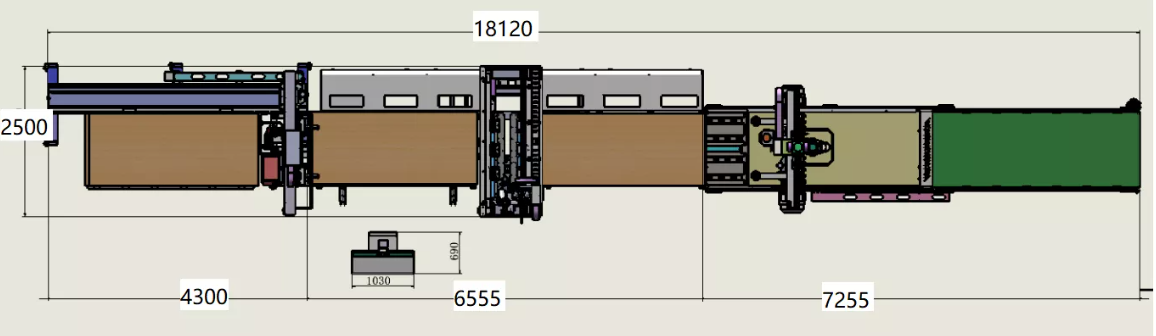

Overall dimension | 16800*2700*2300mm |

ch

ch English

English