ICW368 Automatic edge banding machine

Edge thickness | 0.4-3mm |

Tape thickness | 12-62mm |

Panel thickness | 10-60mm |

Heating power | 2.0kw |

Conveyor belt speed | 12-20m/min |

Air pressure | 0.6Mpa |

Total motor power | 9kw |

Dimension | 4500*900*1550mm |

Net weight | 1700kgs |

Edge thickness | 0.4-3mm |

Tape thickness | 12-62mm |

Panel thickness | 10-60mm |

Heating power | 2.0kw |

Conveyor belt speed | 12-20m/min |

Air pressure | 0.6Mpa |

Total motor power | 9kw |

Dimension | 4500*900*1550mm |

Net weight | 1700kgs |

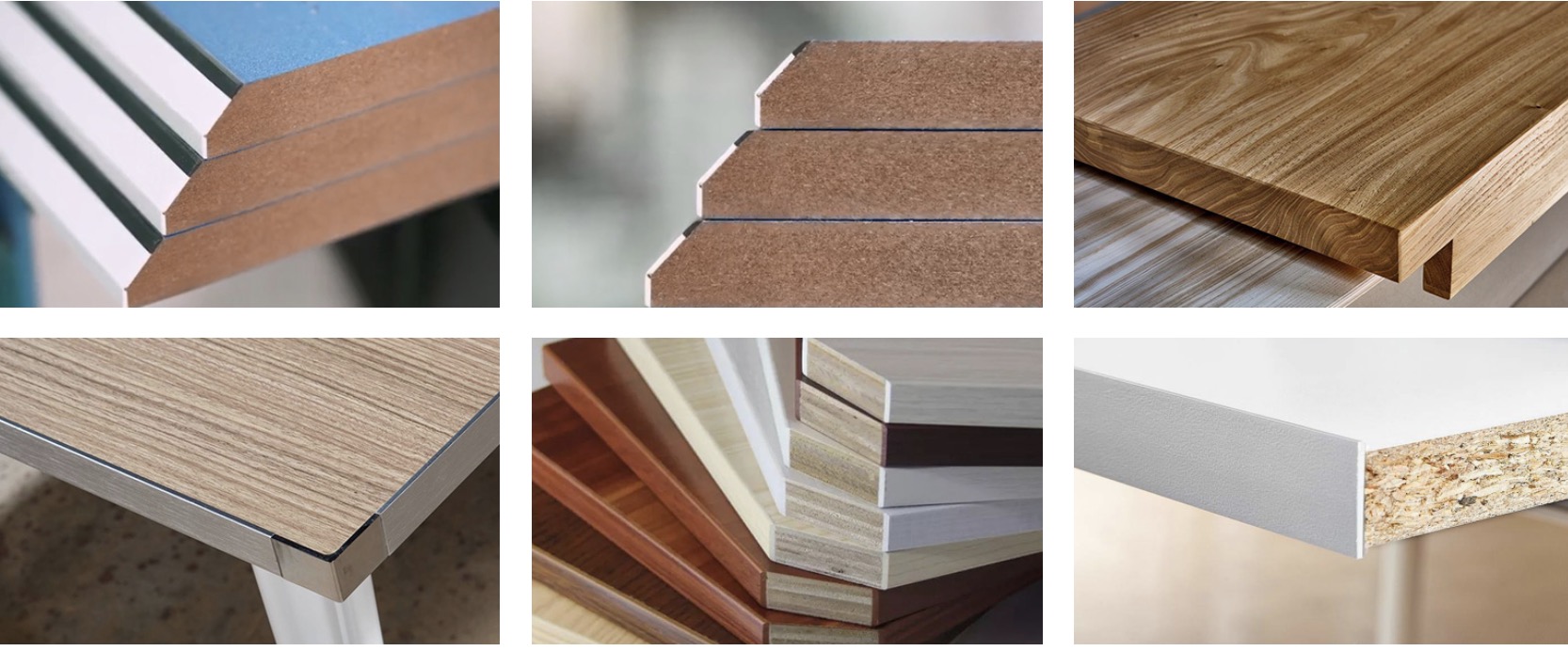

Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material

Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material. Common substitutes for edgebanding include face frames or molding. Edge banding can be made of different materials including PVC, ABS, acrylic, melamine, wood or wood veneer.

Advantage:

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

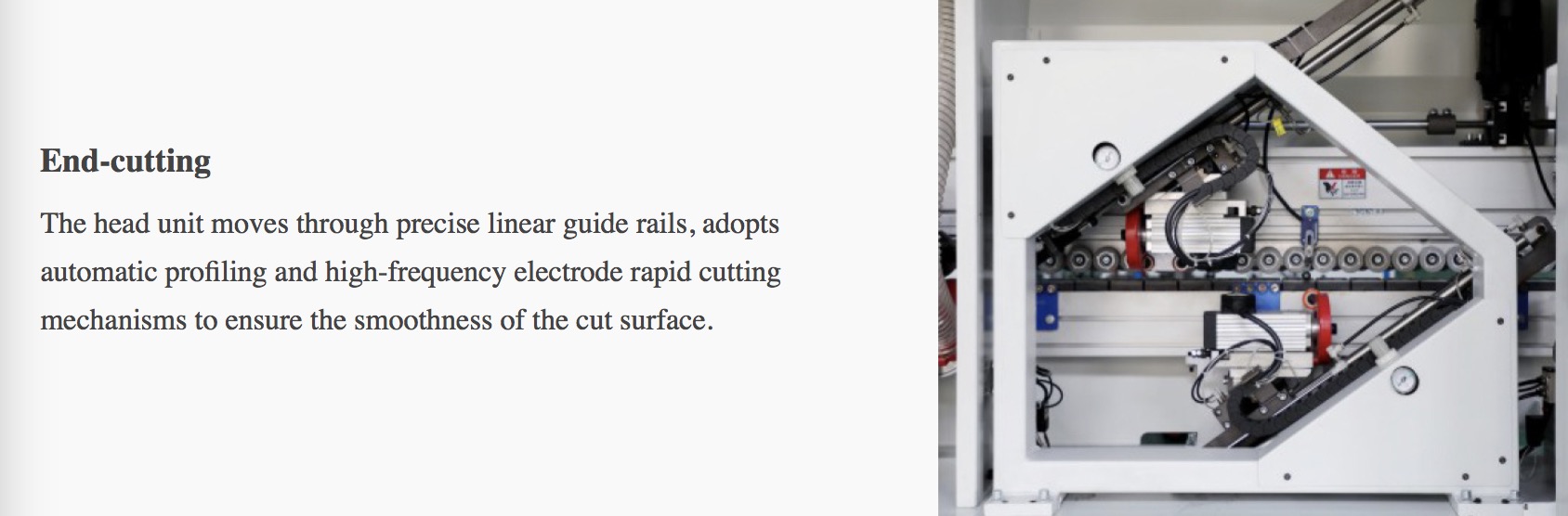

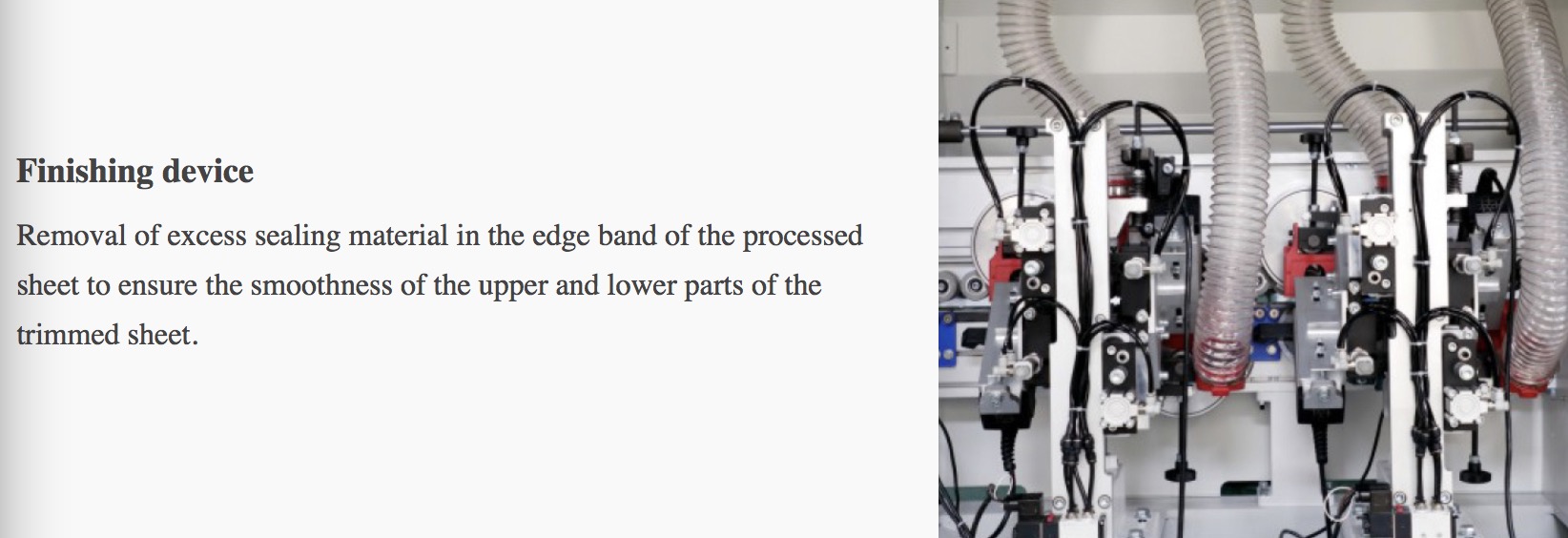

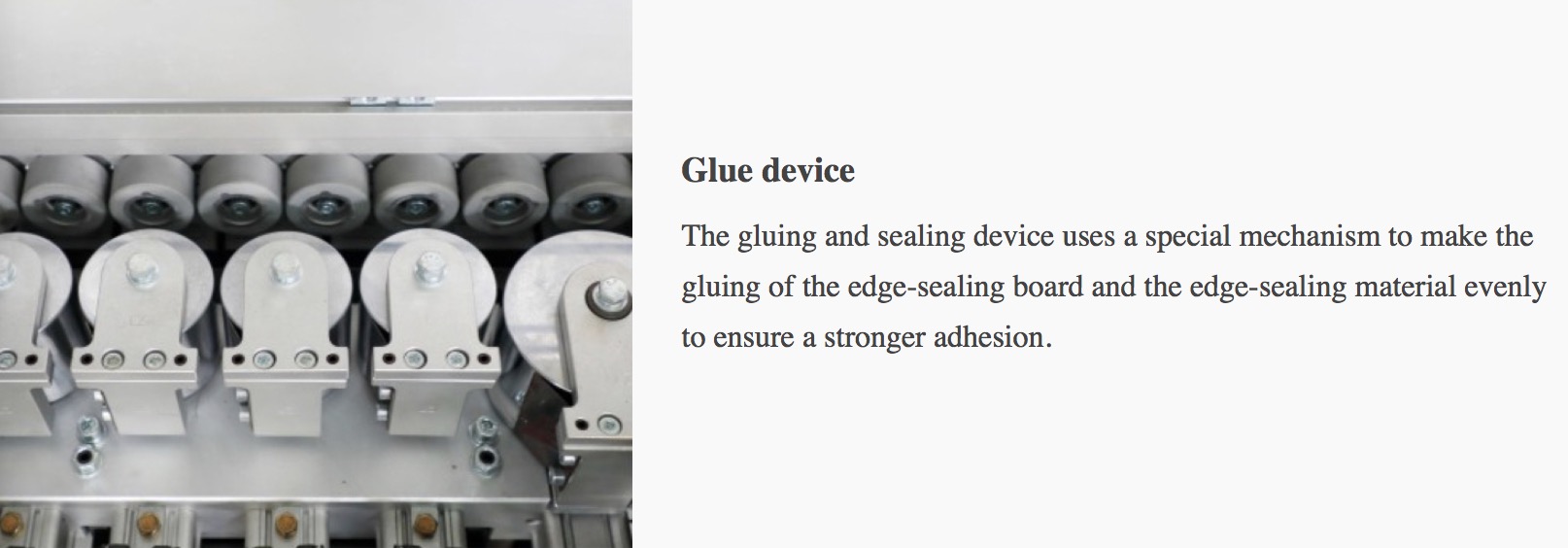

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used for positioned location assured the panel materials processing accuracy in a very high level.

8.Secondary Dust Exhaust System, mainly used for sawdust collection during processing period, to keep the material smooth and

clean.

9.The machine adopts the devices of sound insulation, controlling of dust, platform frame Micro adjustment by manual operation.

Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material

Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material. Common substitutes for edgebanding include face frames or molding. Edge banding can be made of different materials including PVC, ABS, acrylic, melamine, wood or wood veneer.

Factory & Workshop View:

We Were Established In 2004 Manufacturing With Ce,Bv And Sgs,Workers Over 300 Persons, 50

We Produce Main Goods Such As Woodworking Machine,Sliding table saw, Edge bander machine,NC boring machine,

Cnc Router Machine,Penumatic Auto Change Wood Cnc Router

.We will take care of your machinery packages well like picture show.

·Our workers will make sure your cnc machine clean before package.

·We will add stretchy film for the whole machine and spare parts for delicate protection.

·We will make export standard strong Wooden box case package as your request.

·Technical support by Phone, Email, Wechat and WhatsApp , 24 hours online.

·We provide English version manual and Operational video.

·Our machine is installed and tested well before delivery. You can operate the machine immediately after receiving machine.

·If you don’t know how to use the machine, we will offer you free training until you can use machine freely. And If there is still

have any question, please contact us by Email, Skype, Wechat, WhatsApp, Phone and online service at any time.

A comprehensive range of technologies and solutions for Furniture | Doors | Cabinets.